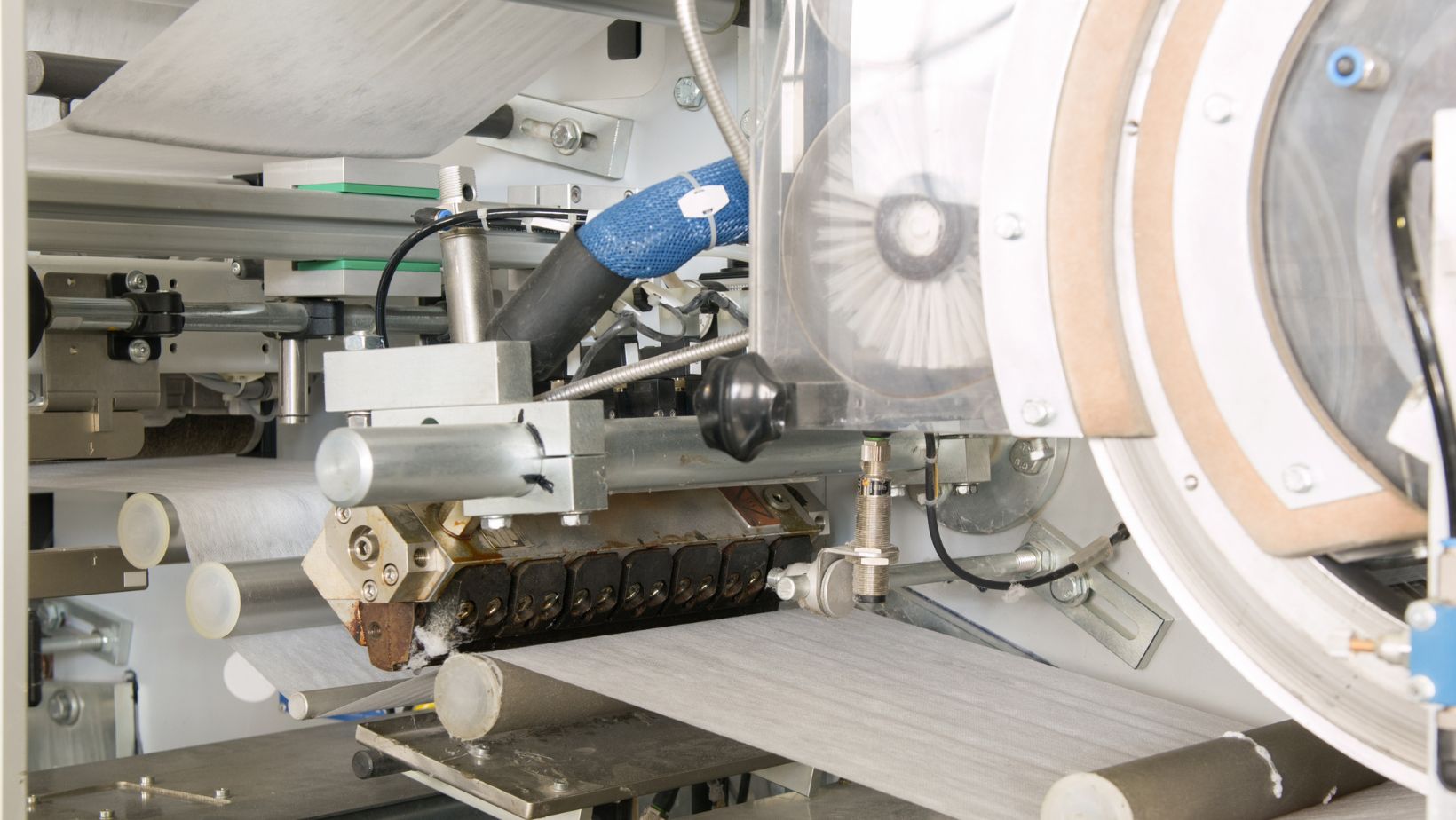

Selecting the right rotating conveyor speed is crucial for manufacturing efficiency and product quality, as incorrect speeds can lead to significant production issues and damaged goods. What are the key factors when selecting the appropriate rotating conveyor speed?

The key factors for selecting a rotating conveyor speed include product weight and fragility, conveyor load capacity, material flow requirements, and system throughput targets. Depending on these variables, most rotating conveyors operate between 10-100 feet per minute.

While this answer provides a basic framework, it’s important to continue reading as specific industries and product types may require unique speed considerations outside these general guidelines. Understanding these exceptions could be the difference between optimal performance and costly operational inefficiencies.

How Do Different Industries Require Different Rotating Conveyor Speeds?

In the food and beverage industry, conveyor speeds typically run slower, around 10-30 feet per minute, to prevent product damage and maintain precise packaging alignment. Delicate items like baked goods or glass bottles require gentle handling to prevent breakage or deformation.

Conversely, the automotive industry often operates conveyors at higher speeds, between 60-100 feet per minute. These faster speeds are possible because automotive parts are generally more durable,and the emphasis is on maximum throughput rather than careful handling.

What Role Does Product Weight Play In Determining Conveyor Speed?

Heavy products naturally require slower conveyor speeds to maintain control and prevent system strain. Items weighing over 50 pounds typically necessitate speeds under 40 feet per minute to ensure proper handling and worker safety. Additionally, heavier items need more time to accelerate and decelerate, making slower speeds essential for smooth transitions between conveyor sections.

Light products weighing under 5 pounds can often be conveyed at higher speeds, sometimes exceeding 80 feet per minute. However, considerations must be made for product stability and air resistance, as lighter items can become unstable or even airborne at excessive speeds.

How Does System Layout Impact Optimal Conveyor Speed?

Complex rotating conveyor systems with multiple turns, merges, or elevation changes require careful speed considerations. Turns and curves typically need 20-30% slower speeds than straight sections to prevent product shifting or tipping. Similarly, inclines and declines usually require up to 40% speed reductions compared to level sections.

The number of transfer points in a system also affects speed selection. Each transfer point represents a potential bottleneck, and speeds must be coordinated between connecting conveyors to ensure smooth product flow.

Generally, speeds should be slightly faster at the receiving conveyor to prevent product accumulation at transfer points.

What Safety Considerations Affect Rotating Conveyor Speed Selection?

Worker interaction with the conveyor system plays a crucial role in speed selection. Areas where employees need to pick items from the conveyor manually, should maintain speeds below 40 feet per minute to ensure safe handling. This slower speed reduces the risk of repetitive strain injuries and allows workers to maintain accurate picking without rushing.

Emergency stopping distances must also be factored into speed decisions. Higher speeds require longer stopping distances, which may not be practical in confined spaces or areas with frequent worker interaction. OSHA guidelines recommend that conveyors should be able to stop within the distance a product travels in one second at operating speed.

How Do Environmental Conditions Impact Conveyor Speed Decisions?

Temperature and humidity levels can significantly affect appropriate conveyor speeds. In cold storage environments (below 40°F), speeds often need to be reduced by 15-25% compared to room temperature operations due to changes in material properties and increased friction on conveyor components.

High-humidity environments may require speed adjustments to prevent product slippage, particularly on inclined sections. Similarly, dusty or dirty environments might necessitate slower speeds to prevent excess wear on conveyor components and ensure consistent product tracking.

Regular cleaning and maintenance become even more critical in these conditions, as build-up can affect speed consistency and system performance. In climate-controlled environments, speeds can typically be maintained at optimal levels, as consistent temperature and humidity help ensure reliable performance and predictable product behavior during transport. However, transitions between different environmental zones (such as moving from a freezer to a room temperature area) may require speed adjustments to account for condensation or temperature-related changes in product characteristics.

Taking The Next Steps With Your Conveyor System

Before making any final speed adjustments to your rotating conveyor system, conduct a thorough audit of your specific operation, documenting product characteristics, environmental conditions, and worker interaction points. Then, use this information alongside the above factors to create a detailed speed map for different sections of your conveyor system, testing and adjusting speeds gradually to find the optimal balance between efficiency and safety.